how to use a rockwell hardness tester|rockwell hardness tester diagram : Brand manufacturer How to Use a Rockwell Hardness Tester? To perform a Rockwell hardness test, follow these general steps: Prepare The Sample: Ensure the surface of the sample is clean, flat, and free from any contaminants. Position the sample . Assista vídeos pornô de Putinha Novinha de graça, aqui no Pornhub.com. Descubra a crescente coleção de vídeos e filmes Mais relevantes explícitos em alta qualidade. .

{plog:ftitle_list}

web24 de abr. de 2023 · Deixa o like e se inscreve aí para dar uma força Jogo: Exército Brasileiro "EB" Criador (a) do jogo: Apex_Hard. TODOS OS CÓDIGOS DE GANHAR DINHEIRO NO EXÉRCITO .

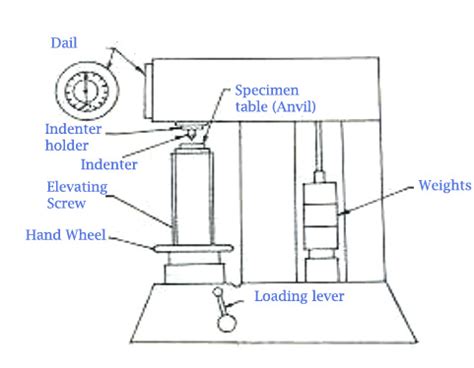

Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test .

In this video I go over the Rockwell Hardness test with an analog machine.How to Use a Rockwell Hardness Tester? To perform a Rockwell hardness test, follow these general steps: Prepare The Sample: Ensure the surface of the sample is clean, flat, and free from any contaminants. Position the sample . This video will show you how to use the Rockwell hardness tester with both the B and C scales.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as .

The Rockwell hardness test is a measuring system used to determine how resistant a material is to another object. Grab this complete guide. Tutorial video on how to use rockwell hardness tester.For Scale B Tests.

The Starrett 3814 accurately measures hardness of materials in Rockwell hardness A, B, and C scales. Heat-treated steels are tested using a 120 diamond indenter in the C-scale (HRC 20 .The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .

How to get a hardness reading using an electronic Rockwell hardness tester. In this video, we use a Rockwell B scale with a flat sample. For HVCC students, t.

Ever wondered what the Rockwell scale really means? What number on the scale is a "good" degree of hardness? How to measure the hardness of your part? Or wha.If a Rockwell test is conducted on cylindrical parts, then, due to the lower resistance of the test surface with respect to the indenter, the following correction values – depending on the specimen curvature radius and the Rockwell scale used – must . Tutorial video on how to use rockwell hardness tester.For Scale B Tests.

This video will show you how to use the Rockwell hardness tester with both the B and C scales.Rockwell hardness tester is an innovative instrument in the field of hardness testing, offering a comprehensive solution for material analysis. Whether you are examining metals, alloys, plastics, or ceramics, this instrument can provide precise harness measurements vital for quality control, material selection, and process optimization.How to Use a Rockwell Hardness Tester? To perform a Rockwell hardness test, follow these general steps: Prepare The Sample: Ensure the surface of the sample is clean, flat, and free from any contaminants. Position the sample securely on the anvil of the Rockwell hardness tester. A must for most any machine shop! An easy-to-use, dramatically less expensive alternative to a Benchtop Hardness Tester, the TTC Hardness Tester File Set all.

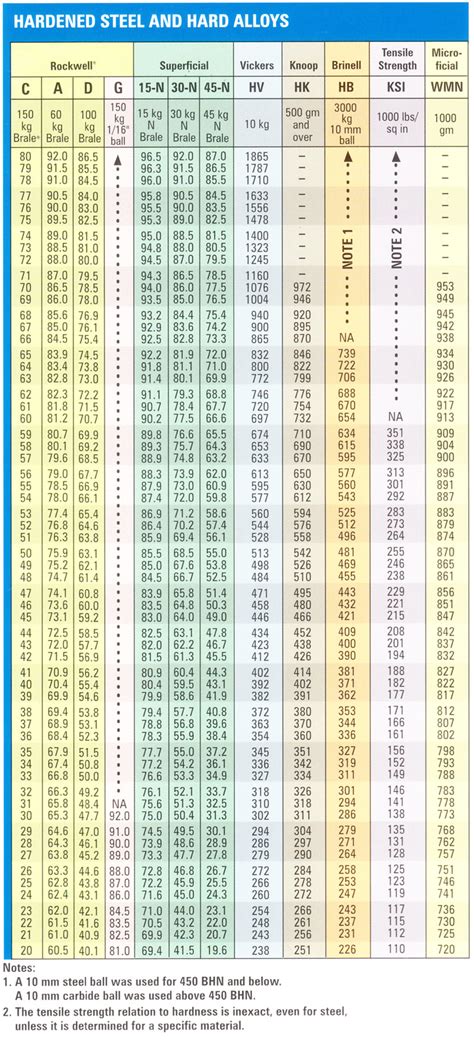

Performing hardness testing can take many forms, depending on the protocols followed. There are many hardness scales and one of the most common is the Rockwell scale. To convert Rockwell Hardness to Tensile Strength, use a polynomial equation developed by modeling the tested materials. The general formula is: TS = c3 * RH^3 + c2 * RH^2 + c1 . What are the precautions for the use of a Rockwell hardness tester? (1) Regularly inject a small amount of oil into the contact surface of the screw and the handwheel; (2) Before using the Rockwell hardness tester, clean the top surface of the screw and the upper-end surface of the worktable; (3) Regularly check with a standard hardness block . Tina [email protected]+86-13818915684Many Rockwell test standards also stated that while processing the test, there should be a distance of more than 2.5 times the diameter of the indentation between mid of an indentation and the periphery of the material. Thickness of Test Material In the Rockwell hardness test, indentation depth depends on the thickness of the material.

Rockwell hardness test: Rockwell hardness test with the method of measuring pressure depth, hardness value through instructions direct reading, therefore, simple and convenient operation, easy to grasp, high efficiency, suitable for batch parts inspection; Rockwell hardness test method, can use diamond indenter andThe Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions.

profiles. The Rockwell test is the most popular indentation hardness test and is used in a wide variety of applications. Advantages of the Rockwell Test There are several reasons for the popularity of the Rockwell test. The test itself is very rapid. On a manually operated unit, a Rockwell test takes only five to ten seconds, In this video I go over the Rockwell Hardness test with an analog machine. This is a Wilson machine.I talk about the setup for Rockwell “A” , “B” and “C” tes.If a Rockwell test is conducted on cylindrical parts, then, due to the lower resistance of the test surface with respect to the indenter, the following correction values – depending on the specimen curvature radius and the Rockwell scale used – must . This video is about using a Rockwell hardness tester, and, showing the main components. With the help of Robert and Philippe I'll give a description of the.

A must for most any machine shop! An easy-to-use, dramatically less expensive alternative to a Benchtop Hardness Tester, the TTC Hardness Tester File Set allows you to quickly ascertain the hardness of your material. Watch resident tech expert Kurt Repsher demonstrate how to use Rockwell Hardness Tester Files in this video, and subscribe to our channel to see more .

wilson rockwell hardness tester repair

Many Rockwell test standards also stated that while processing the test, there should be a distance of more than 2.5 times the diameter of the indentation between mid of an indentation and the periphery of the material. Thickness of Test Material In the Rockwell hardness test, indentation depth depends on the thickness of the material. What are the precautions for the use of a Rockwell hardness tester? (1) Regularly inject a small amount of oil into the contact surface of the screw and the handwheel; (2) Before using the Rockwell hardness tester, clean the top surface of the screw and the upper-end surface of the worktable; (3) Regularly check with a standard hardness block .

Rockwell Hardness Testing Machine HR-530 Series Unique electronic control makes the HR-530 series of hardness testers capable of Rockwell, Rockwell Superficial, Rockwell testing of plastics (A & B) and Light Force Brinell hardness testing. .Model No. PHT-1900 Features. State of the art, digital portable hardness tester is designed to test the hardness of large hard metal parts. Clean crisp display shows the incredible functions that can only be found on this new portable hardness tester such as auto-probe detection, auto direction detector, single and multi-point calibration make the new 1900 the most versatile . Using An Ames Portable Metal Hardness Tester Find more helpful videos on our youtube channel.Below is a transcript of the above video. If you have any questions or need more information on our portable Rockwell testers than contact us here. We’re going to be testing a customer’s sample piece on her Model 1 a standard Ames portable hardness tester.

Operating a 1940's Wilson model 3JR Rockwell hardness tester.Harvey Mudd College machine shop, 2022.

Testing a few things around the shop on my hardness tester Model HR-150A. This unit is made in China, but seems to work just fine. I have nothing to compare .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

Polarimeter vendor

Resultado da 5 de dez. de 2023 · Acompanhe o sorteio da Mega Sena 2664 e confira o resultado do dia 05 de dezembro de 2023, terça-feira, com o prêmio de .

how to use a rockwell hardness tester|rockwell hardness tester diagram